博文

镁合金腐蚀研究进展(19)—镁合金表面旋涂层层组装涂层耐蚀性能

|||

镁合金表面旋涂层层组装涂层耐蚀性能

层层自组装(layer-by-layer self-assembly,LBL)是上世纪90年代发展起来的一种操作简单、实现多功能的表面修饰方法。LBL主要利用静电、氢键等作用,即:带电基板在带相反电荷的聚电解质溶液中交替沉积制备聚电解质自组装多层膜(polyelectrolyte self-assembled mulilayers)。

多层薄膜在催化、光学、能源、薄膜、生物医学等领域有广泛的应用,从而引起了高度关注。当前采用层层自组装获得多层薄膜的技术路线包括:浸涂、旋涂、喷涂、电磁沉积和流体组装。选择合适的组装技术可达到裁剪涂层物理化学性质的目的[1]。

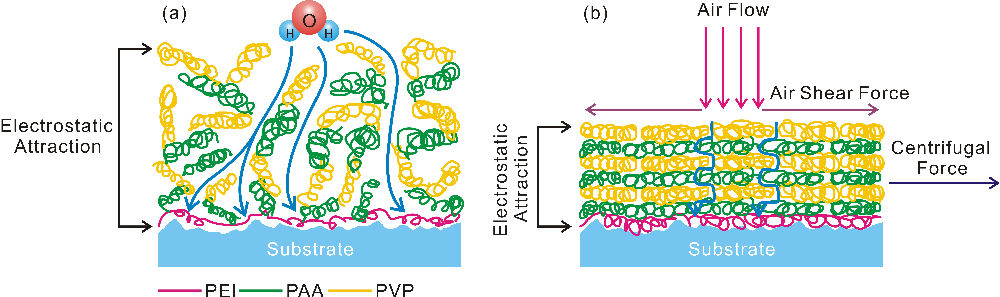

浸涂法(Dip-coating, DC)层层组装是镁合金表面制备层层组装涂层的常用方法。然而,当镁合金被完全地浸没于电解质溶液之中,样品会出现不同程度的腐蚀(浸泡时间、取样速度、pH、表面均匀性等的因素的影响),所制备涂层的耐腐蚀性有限。为解决此问题,旋涂法(Spin-casting, SC)或许是不错的选择。

其原理为:在旋涂的过程中,由于样品的高速旋转,在镁合金表面会产生空气剪切力和离心力,在这两种力的作用下,滴在样品表面上的聚电解质中的水分子会被快速甩掉,进而得到均匀而且致密的涂层。

Highlights

1. Adefect-free, dense and uniform coating was prepared by the spin-casting technique.

2. The spin-casting filmhad stronger hydrogen bonds than the dip-coating film.

3. Spin-castingsample possessed excellent corrosion resistance and adhesion strength.

4. Spin-casting method could well promote the formation of hydroxyapatite inHBSS.

亮点

1.旋涂法制备了一种无缺陷、均匀且致密的涂层;

2.旋涂法制备的涂层,其不同的电解质之间形成了更强的氢键;

3.旋涂法制备的涂层,具有更显著的耐腐蚀性和更强的结合力;

4.旋涂法制备的涂层,在HBSS溶液中可以促进羟基磷灰石的形成。

该项工作发表在 Applied Surface Science, 2018, 434: 787–795.(可免费下载)

Fig. 1. Schematic diagram ofthe internal structure of the (PVP/PAA)10 films prepared by (a) D-C methodand (b) S-C method.

Fig.2. SEM morphology of (a, d)the D-C film, (b, e) the S-C filmand(c) the AZ31 substrate, (f) the elementalcomposition from point 1 to point 12.

Fig. 3. FT-IR spectra of(a) pure PVP, (b) pure PAA, (c) the D-Cfilm and (d) the S-C film.

Fig.4. Scratch results of (a) the D-C film and (b) the S-C film.

Fig. 5. Schematicillustration of the corrosion mechanism of the (PVP/PAA)10 films onAZ31 Mg alloys in HBSS.

相关文献

[1] Joseph J. Richardson, Mattias Björnmalm, Frank Caruso. Technology-driven layer-by-layer assembly of nanofilms. Science, 2015, 348(6233), aaa2491.

[2] L.Y. Cui, S.D. Gao, P.P.Li, R.C. Zeng, F. Zhang, S.Q. Li, E.H. Han, Corrosion resistance of aself-healing micro-arc oxidation/polymethyltrimethoxysilane composite coatingon magnesium alloy AZ31, Corros. Sci. 118 (2017) 84–95.

[3] L. Cui, R.C. Zeng, S. Li,F. Zhang, E.H. Han, Corrosion resistance of layer-by-layer assembledpolyvinylpyrrolidone/polyacrylic acid and amorphous silica films on AZ31magnesium alloys, RSC Adv. 6(2016) 63107-63116.

[4] Lan-Yue Cui, Peng-Hua Qin,Xiao-Li Huang, Zheng-Zheng Yin, Rong-Chang Zeng*,Shuo-Qi Li*,En-Hou Han, Zhen-Lin Wang. Electrodepositionof TiO2 layer-by-layer assembled composite coating and silane treatment on Mg alloy for corrosion resistance. Surface & Coatings Technology. 324 (2017) 560–568.

[5] Lan-Yue Cui, Rong-Chang Zeng*, Xiao-Xiao Zhu, Ting-Ting Pang, Shuo-Qi Li*, Fen Zhang. Corrosion resistance of biodegradable polymeric layer-by-layer coatings on magnesium alloy AZ31. Frontiers of Materials Science, 2016, 10(2): 134–146.

[6]Lan-Yue Cui, Ji Xu, Na Lu,Rong-Chang Zeng*, Yu-hong Zou, Shuo-Qi Li*, Fen Zhang. In vitro corrosion resistance andantibacterial properties of layer-by-layer assembled chitosan/ poly-L-Glutamicacid coating on AZ31 magnesium alloys. Transactions of Nonferrous Metals Society of China, 27(2017)1081−1086.

[7]Rongchang ZENG, Lijun LIU, KaijieLUO, Li SHEN, Fen ZHANG, Shuoqi LI, Yuhong ZOU. In vitro corrosion and antibacterial properties of layer-by-layer assembled GS/PSS coating on AZ31 magnesium alloys. Transactions of Nonferrous Metals Society of China, 25(2015)4028−4039.

https://blog.sciencenet.cn/blog-114283-1084359.html

上一篇:课题组召开镁合金材料研讨会

下一篇:镁合金腐蚀研究进展(20)—Mg-1Li-1Ca表面MAO/SA超疏水涂层