博文

镁合金腐蚀研究进展(24)—第二相Mg2Ca对Mg-Li-Ca合金MAO的影响

|||

镁合金腐蚀研究进展(24)—第二相Mg2Ca对Mg-Li-Ca合金MAO的影响

微弧氧化(MAO)又称等离子体电解氧化,通过弧光放电在基体表面原位生长金属氧化物,是镁合金表面处理的重要手段之一。但微弧氧化层包含有大量的微孔和微裂纹,导致其不能长时间保护基体。

目前,对于镁合金微弧氧化的研究目前主要集中在对电解液配方及相关参数,膜层物化性质,涂层的封孔等方面,并取得了重要的进展。然而,微弧氧化膜的性质主要由基体材料本身物理、化学性质决定。有关镁合金表面微弧氧化膜成膜机理,特别是第二相的影响还缺乏充分的研究。

本项工作对挤压态Mg-1Li-1Ca进行微弧氧化处理,考察了第二相Mg2Ca对微弧氧化成膜过程的影响,揭示第二相Mg2Ca对基体材料微弧氧化行为的影响机理;同时,研究了第二相对微弧氧化膜层腐蚀的影响,提出第二相对膜层降解破坏的微观机制,为多相镁合金微弧氧化工艺的改进及氧化膜的组织性能控制提供理论参考依据。

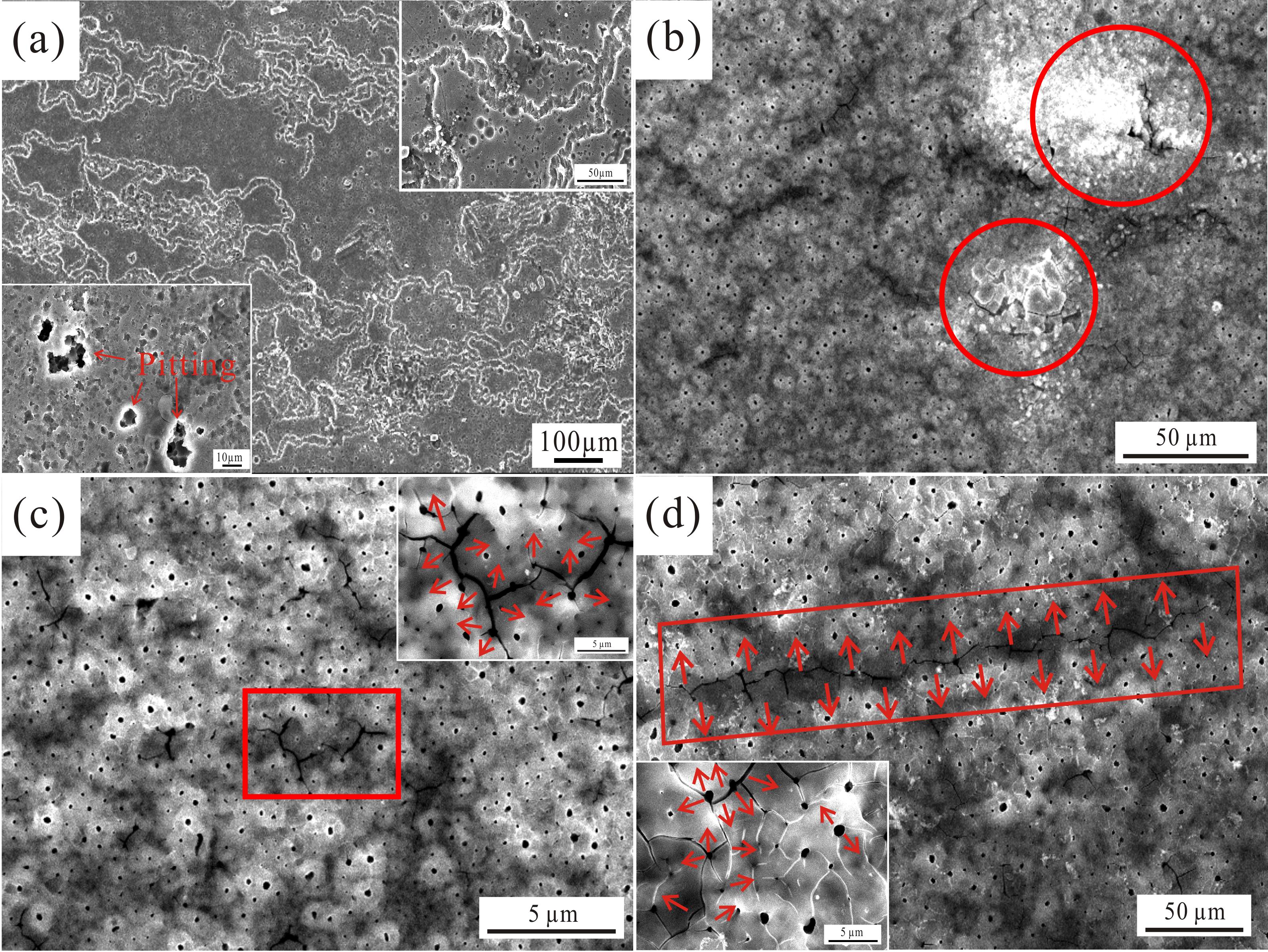

研究表明,挤压态Mg-1Li-1Ca合金表面存在点蚀和丝状腐蚀。其表面MAO膜内层主要是由MgO组成,外层则是由MgSiO3组成。MAO膜显著提高了Mg-1Li-1Ca耐蚀性能。因为Ca元素的阻燃性,Mg-1Li-1Ca微弧氧化萌生于α-Mg 相的贫Ca区。MAO涂层在α-Mg 基体上的生长速率高于在GBs/Mg2Ca界面上的生长速率。MAO 涂层的降解从Mg2Ca开始。

Abstract: The presence of second phase Mg2Ca has remarkable impacts on the formation and degradation of MAO coating. Microstructure, formation and degradation behaviors of substrate and MAO coating were performed. Results revealed that pitting and filiform corrosion occurred on bare Mg-1Li-1Ca alloy. MAO coating significantly improved the corrosion resistance of alloy. The roles of Mg2Ca on the formation and degradation mechanisms of MAO coating were discussed. Micro-arc oxidation for the Mg-Li-Ca alloy initiated at α-Mg phase with depleted Ca content. The growth rate of coating on α-Mg phase is faster than that of GBs/Mg2Ca. The MAO coating began to degrade from intermetallic compound Mg2Ca, then it underwent the attack from the solution and stress concentration caused by corrosion products.

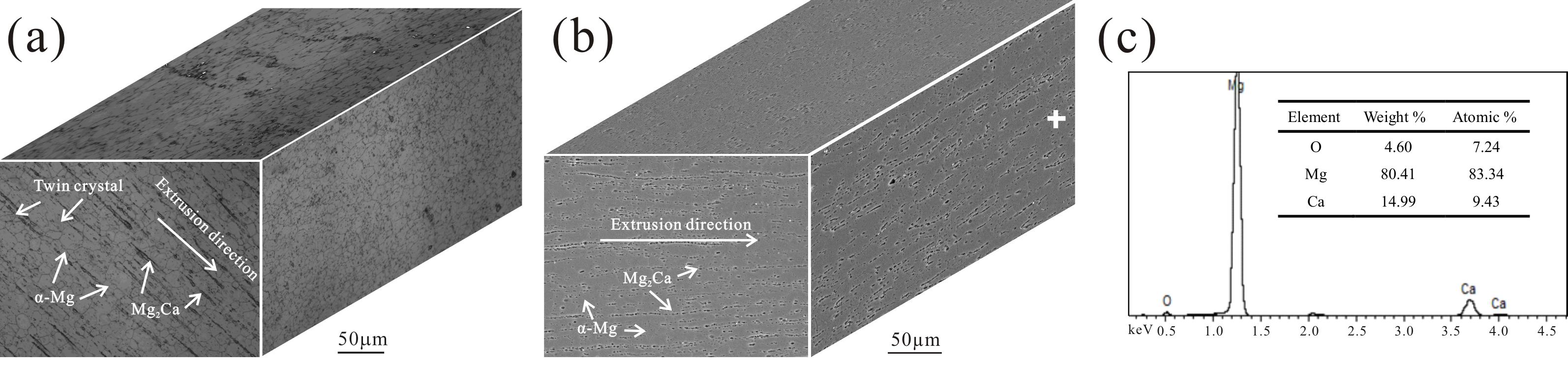

Fig. 1 Microstructure of Mg-1Li-1Ca alloy and EDS of Mg2Ca

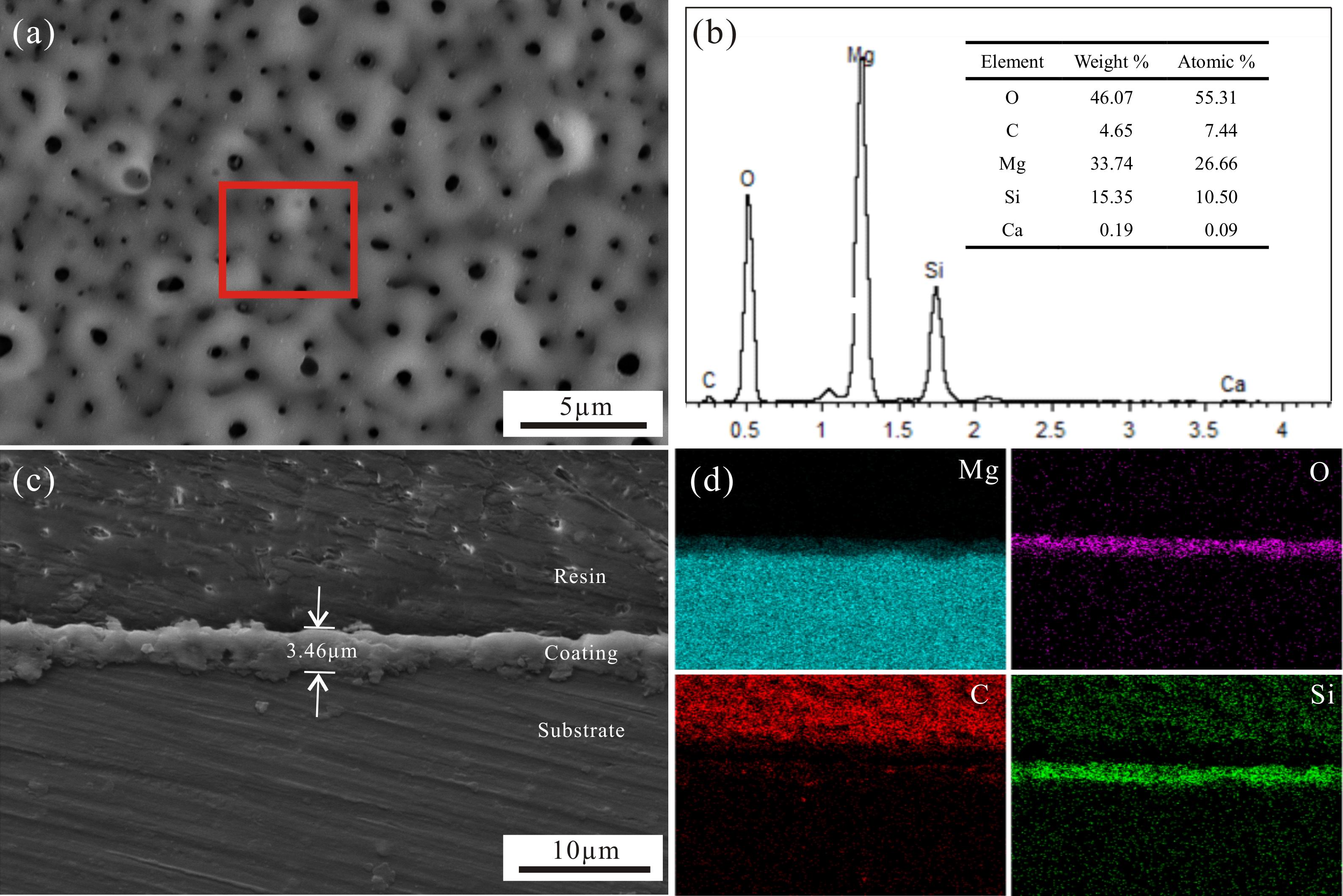

Fig. 2 SEM images of (a) MAO coating and its (b) EDS patterns,EPMA images of (c) cross-sectional view of MAO coating and its (d) EDS mapping.

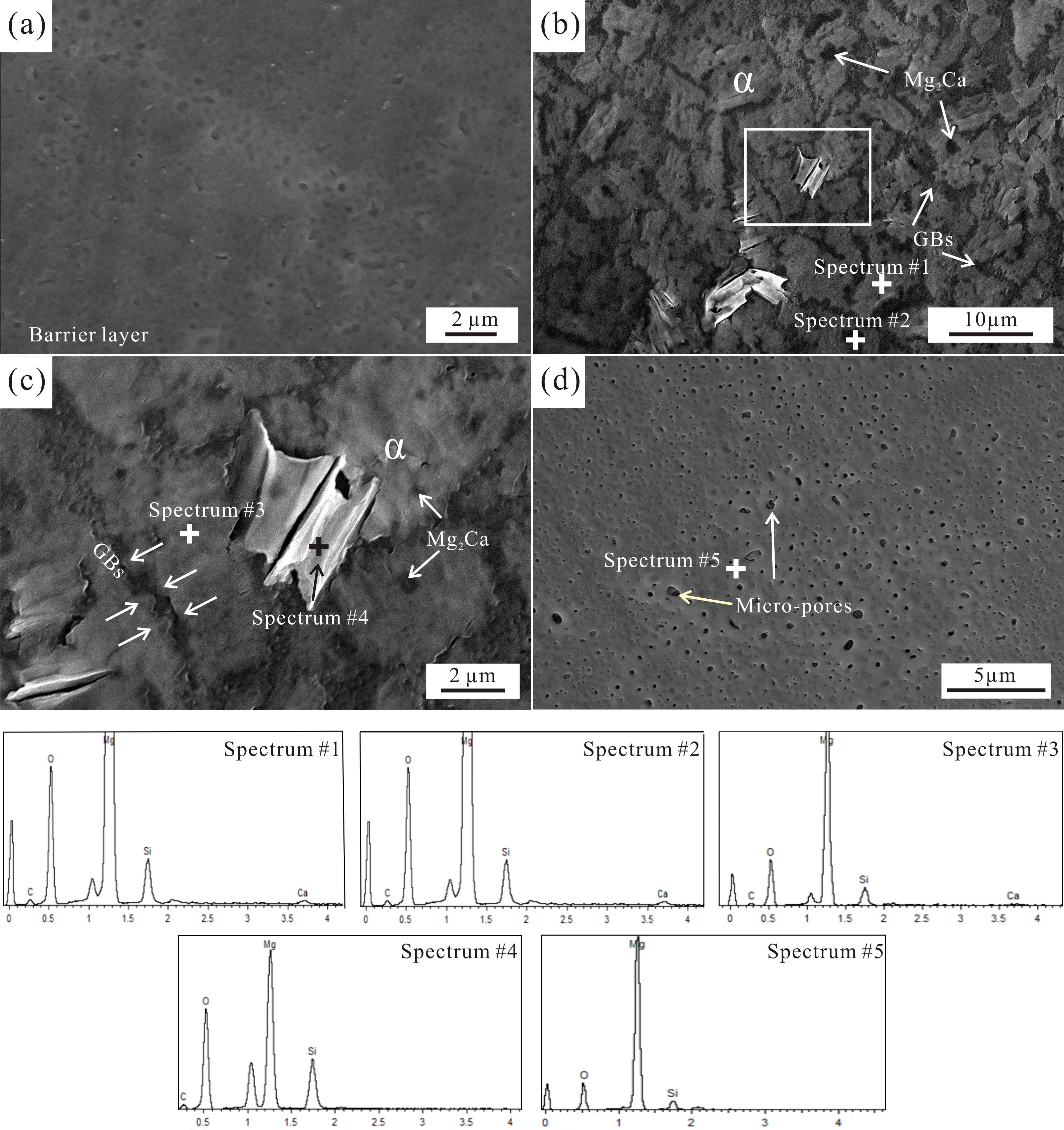

Fig. 3 Morphology of MAO coating obtained (a) before and after appearance of arc discharges for 5 s (b) (c), 10s (d) and EDS spectrum.

Fig. 4 Formation mechanism illustration during micro-arc oxidation preparation: (a) before and (b) after appearance of arc discharges (c) 5 s, (d) 10 s.

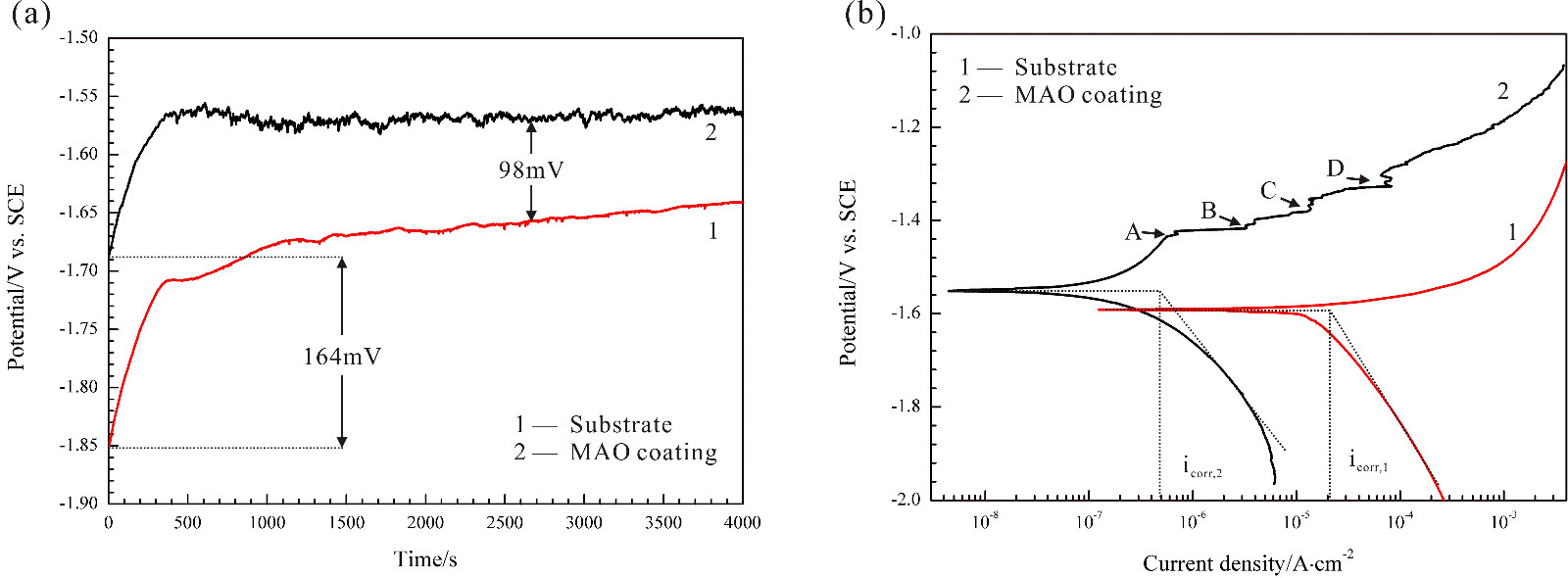

Fig. 5 Potential as a function of time (a) and polarization curves (b)

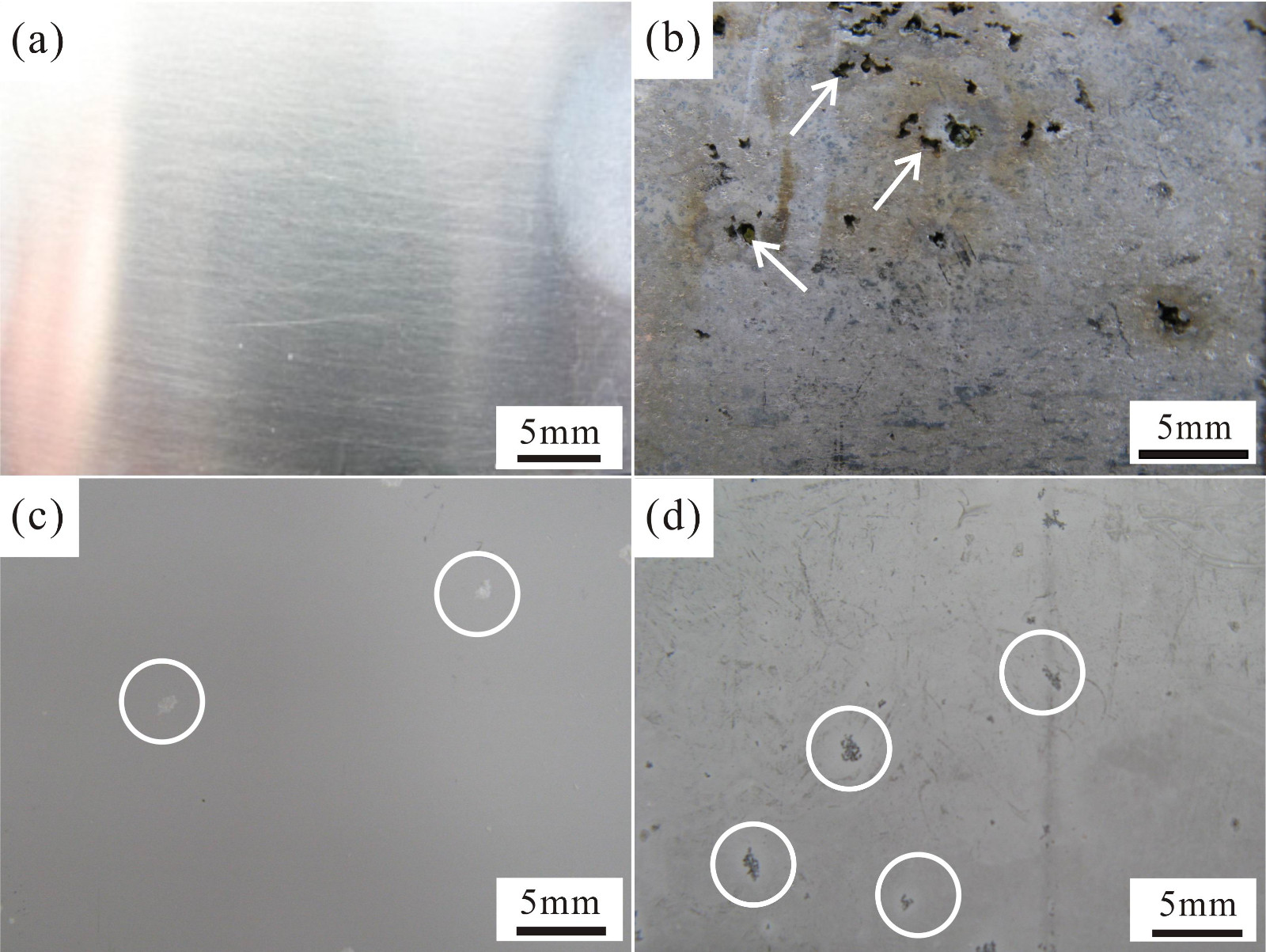

Fig. 6 Macroscopic corrosion morphology: substrate of immersion for (a) 0 h, (b) 144 h, MAO coating of immersion for (c) 0 h, (d) 144 h in Hank’s solution.

Fig. 7 Corrosion morphologies: Mg-1Li-1Ca (a) substrate and (b-d) MAO coating after an immersion of 144 h.

Fig. 8 Degradation mechanism illustration for (a) (b) (c) surface and (d) (e) (f) sectional view of Mg-1Li-1Ca alloy coated MAO coating in Hanks’ solution.

该论文(In vitro corrosion of micro-arc oxidation coating on Mg-1Li-1Ca alloy — The influence of intermetallic compound Mg2Ca)已发表在国际期刊《Journal of Alloy and Compounds》( Zi-You Ding et al.,764 (2018) pp. 250-260),并受到国家自然科学基金(51571134, 51601108)和山东科技大学校级团队经费(2014TDJH104)资助。

链接:

曾荣昌发表论文目录(Rong-Chang Zeng\'s Publications)(2000-)

https://blog.sciencenet.cn/blog-114283-1118049.html

上一篇:镁合金腐蚀研究进展(23)—挤压镁锂钙合金的剥蚀

下一篇:中车青岛四方机车车辆林化强博士来课题组交流

全部作者的精选博文

全部作者的其他最新博文

- • 五律 谷雨

- • 回忆录(1)-我的教授梦

- • 五律 紫荆

- • 1995-2023年优秀论文目录

- • 七绝 海棠

- • 踏莎行(晏殊体) 锗(Germanium)